VSP-G1 User Manual: Difference between revisions

T.pfeiffer (talk | contribs) |

T.pfeiffer (talk | contribs) |

||

| Line 358: | Line 358: | ||

<span style="background:#FFFF00"> TVP and Vincent: consider adding how-to videos</span><br> | <span style="background:#FFFF00"> TVP and Vincent: consider adding how-to videos</span><br> | ||

There are several [[VSP-G1 Maintenance protocols|maintenance protocols]] for the VSP-G1. Although the system requires no regular maintenance, cleaning the reactor periodically is recommended, especially after a change of electrode material. To prevent exposure to nanoparticles and to ensure safe and efficient cleaning, follow the protocols set out in the [[VSP-G1 Maintenance protocols|Maintenance protocols]] section. The procedure to replace electrodes is also discussed there. | There are several [[VSP-G1 Maintenance protocols|maintenance protocols]] for the VSP-G1. Although the system requires no regular maintenance by the end user, cleaning the reactor periodically is recommended, especially after a change of electrode material. To prevent exposure to nanoparticles and to ensure safe and efficient cleaning, follow the protocols set out in the [[VSP-G1 Maintenance protocols|Maintenance protocols]] section. The procedure to replace electrodes is also discussed there. | ||

=== Safe handling and storage === | === Safe handling and storage === | ||

Revision as of 09:44, 28 March 2017

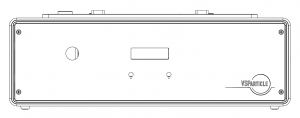

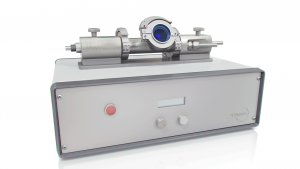

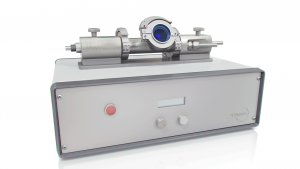

This is the comprehensive User Manual for the VSParticle Generator One Spark Generator (VSP-G1). The Quick Start Guide is available as a quick reference for standard operation of the VSP-G1 unit.

After completing the User Manual, cross-check the residual risks requirements...if any changes are made to information in the residual risks table (8.5), make sure the corresponding changes are made in the design document.

| Company | VSParticle B.V. |  |

|---|---|---|

| Address | Molengraaffsingel 10 2629 JD Delft The Netherlands | |

| Website | vsparticle.com | |

| Support e-mail | support@vsparticle.com |

Introduction

top

EDIT for content when the manual is finished. Advanced editing: Refer to company website for consistency in language and terminology.

The User Manual provides instructions for the set-up, installation, operation and maintenance of a VSParticle Generator 1 ("VSP-G1") unit.

Wherever a caution ![]() symbol is affixed to the machinery, there are explanatory texts located within the manual (see this section of the detailed system description for a guide to all symbols found on the VSP-G1. ). Other important safety information located within the manual are also labelled with the caution

symbol is affixed to the machinery, there are explanatory texts located within the manual (see this section of the detailed system description for a guide to all symbols found on the VSP-G1. ). Other important safety information located within the manual are also labelled with the caution ![]() symbol.

symbol.

You will also find conformity and warranty information at the very end of this user manual.

A Quick Start Guide is also included for faster set-up as part of the standard operating procedure. For more information regarding safety, more complex operations and troubleshooting and maintenance, refer to this manual first!

If you have any questions or concerns regarding the VSP-G1 unit you have purchased or any information within the provided user documentation, please contact us via the contact details at the top of this page.

The VSP-G1 is designed for use by researchers who want to produce inorganic nanoparticles from conductive materials for applications in fields ranging from cluster research to materials science. The VSP-G1 is a desktop spark generator that uses spark ablation technology to produce aerosol nanoparticles after a high voltage spark evaporates part of two metallic electrodes. Its design is aimed at making the production of nanoparticles as simple as possible, while giving you the flexibility to customise the system by having control over:

- particle size (1 atom to 20 nm)

- ablation rate (~0.01-100 mg/h)

- carrier gas

- electrode material

- gas flow rate (1-30 l/min)

It is also possible to customise the reactor by changing configurations from through flow (the standard configuration offered with the basic VSP-G1 unit) to cross flow, co-flow and combined configurations. The portability of the system also allows it to be integrated into a larger system for more complex operating procedures.

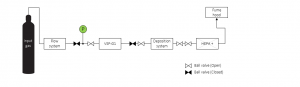

The VSP-G1 is designed as a continuous source of aerosolized nanoparticles for use in a controlled process system. This controlled process system typically comprises a gas source, a gas-tight system of unit operations, valves and tubing, and a gas exhaust fitted with one or more particle filters. Typical conditions in the process system are room temperature and ambient pressure. The system can be run at slight over- or under-pressure.

The closed system provides a safer production of nanoparticles and can easily be dismantled for safe transport of produced nanoparticles and for system cleaning and maintenance, which can be performed following a simple and fast protocol. The closed system design also allows you to produce high purity nanoparticles without any polluting by-products. The spark ablation process eliminates the use of any chemicals, surfactants, precursors or polymers. Without the need to rely on external materials to stabilise the produced particles, you have more flexibility to choose a suitable deposition system for the aerosol nanoparticles. The three physical principles to inmobilize the nanoparticles on a support are diffusion, impaction and electrostatic precipitation. If you have any questions or need help with the selection and/or development of a system that best fits your needs, please contact us.

For more information about the spark ablation process and possible applications, refer to the Background information section.

System and operator safety

Notification: To view a list and description of all warning labels found on the VSP-G1 unit, go to the Guide to symbols found on the VSP-G1

The risks associated with a spark generator can be divided into two categories: those associated with the machine itself, and those associated with nanoparticles. Machine-related risks are more widely regulated by international norms, such as the European conformity system required for marking certain products with the CE symbol. However, synthesized nanomaterials are relatively new and their quantum effects are still being studied, thus there are less standardized measures in place. Until more is known about nanoparticles, we apply the Precautionary Principle, treating them as potential highly toxic materials. The safety measures we employ for working with, storing and transporting nanoparticles have been drawn primarily from those designed for fine particles.

Safety of machinery

The VSP-G1 spark generator comprises general electronics (<50 V), gas connections and high voltage (6 kV), as well as moving parts. Several safety mechanisms mitigate the risk for damages and incidents related to potential equipment failure, but primary responsibility for correct and safe operation lies with you as the operator of the system. The VSP-G1 is intended for use by qualified personnel only.

Operator safety actions

You are required to ensure that:

- the reactor is correctly mounted (see Flow configurations);

- there are no objects near the electrodes (see Flow configurations);

- process connections are correctly made (see Process connections);

- the pressure in the system is limited to ±0.2 bar (see Process connections);

- all, if any, external safety systems are functional (where applicable); and

- personal protective equipment are being used correctly (gloves, glasses, and FFP3/P3 certified filter mask).

Existing protective features

| Warning: Intentional misuse of the VSP-G1 in a manner not specified by VSParticle may impair the existing protective features. |

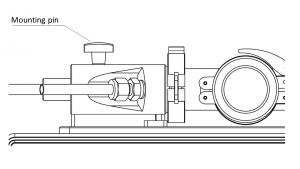

The VSP-G1 is equiped with an interlock system. When a failure is detected, the interlock system cuts power to the high voltage supply and the motor, shutting down particle production. There are three types of interlock.

- Internal Interlock.

During start-up and while running, the VSP-G1 the control system checks if internal systems are working properly. If any check fails an internal interlock is triggered. When the interlock cuts power, you must first fix the conditions that caused the interlock to activate before clearing the interlock state. Press and depress both dials simultaneously to clear the interlock.

- Reactor interlock.

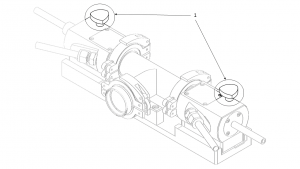

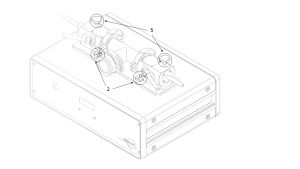

The VSP-G1 detects whether the reactor endcaps are properly mounted, using two mounting pins (see image). You must ensure that the reactor itself is correctly assembled. In short, this means that the reactor is leak tight (see Leak tightness protocol) and that the gas inlet valve and electrode tips are free to move with a minimum clearance of 10 mm from any foreign objects (see Flow configurations).

| Warning: Gas connections and other user-provided functions are not controlled by the interlock. An optional external interlock is available for the VSP-G1. |

- External interlock. (option)

An external interlock switch can be provided for incorporation in an external safety system. To allow operation, two pins of the interlock connector must be connected (shorted). Breaking the connection switches the system into interlock mode.

Other residual risks

Pressure. Pressure within the closed system poses a serious risk when improperly handled. Increased pressure can be caused by unintentional release of gas at high pressure, the closing of output valve while the input valve is open, clogged filters, spark obstruction, or a full deposition system. Exceeding the maximum pressure can lead to failure of the gaskets and seals, and the viewport could explode.

Non-ionizing radiation. The spark plasma emits a bright light in the visible and UV range. A viewport with a removable optical filter is included to allow visual inspection of the electrodes. Additionally, electromagnetic radiation (radio frequency) may be emitted.

Notification: See Residual risks for a comprehensive list of residual risks and how they are mitigated through design features and/or documentation.

Safety of nanoparticles

Because our spark generators can in principle be used to produce nanoparticles from any metal, we start from the assumption that these nanoparticles pose potential risks to the health of operators, consumers and to the environment. This manual addresses operator exposure. Consumer exposure is determined by the application in which the nanomaterials are to be used and should be evaluated on a case-by-case basis by the user. Environmental considerations should also be addressed by the operators with a life cycle analysis.

The main channels of operator exposure to nanoparticles are through (skin) absorption, ingestion and inhalation. The aerosol nature of the produced nanoparticles by the VSP-G1 system means exposure through inhalation is the main risk. The respiratory system of the human body has natural defenses in place for airborne particles such as dust, viruses and bacteria. However, nanoparticles are able to bypass most of these defenses due to their small size. For this reason, nanoparticles are treated in the same way as fine particles. More information on health and safety of nanoparticles can be found through the links at the end of this section.

Operator exposure

While the VSP-G1 unit is designed to be a closed system to maximize safety when working with nanoparticles, there will be situations in which it will be necessary to open the system, including routine maintenance activities, replacement of electrodes and filters, and sample extraction. The list below also includes some possible situations in which the operator may be inadvertently exposed to nanoparticles and a brief summary of the necessary precautions to prevent, wherever possible, such situations.

| Exposure risk situation | Operator precautions |

|---|---|

| Gas phase exposure | An aerosol system must be leak tight from source to deposition (see Leak tightness protocol). |

| Filtration | The gas exhaust should be treated with a suitable HEPA or ULPA filter. VSParticle recommends using a large capacity HEPA pre-filter, followed by an ULPA end filter. |

| Dealing with pyrophoric materials | Metal nanoparticles can be extremely reactive, and can be pyrophoric (spontaneous ignition upon exposure to air).Controlled air-exposure, however, is needed before opening the system in order to passivate any reactive materials (see Controlled-air exposure protocol). |

| Product handling | When the system must be opened to insert or remove a substrate, methods as described in the maintenance protocols section must be followed to reduce the risk of nanoparticle exposure. |

| Maintenance | Nanoparticles will collect on the surfaces inside the reactor and downstream piping. Cleaning of these surfaces presents the largest exposure risk to operators, unless they can be performed in a safe environment (e.g. a glovebox) (see System care for the relevant maintenance protocols).

|

Links to more information on nanoparticles and health

- Health Significance of Nanotechnologies, a report produced by the Health Council of the Netherlands in 2006

- Nanosafety Guidelines, a set of safety recommendations by the workgroup Nanosafety of the Faculty of Applied Sciences of Delft University of Technology for working with ‘free nanostructured matter’ in research activities.

- Good practices for the use of engineered nanomaterials in a research environment, a guide describing good practices for working with engineered nanomaterials by FOM/NWO (The Netherlands Organisation for Scientific Research).

- Nanosafety Quick Check, a checklist developed based on a summary of the Nanosafety guidelines listed above is there a link to this, or can we provide this as a downloadable file? permissions?

- Ten things you should know about nanotechnology, an article available on Nanowerk website

System description

What's in the box

Congratulations on your purchase of the VSP-G1!

In the box you will find the following:

-

The VSP-G1 base unit,

-

a reactor mounted on the base unit,

-

a black viewport cover (possibly mounted on the reactor),

-

a reactor mount plate,

-

and a power supply cable

You will also find a Quick Start Guide for daily operation and a reference card for working with nanoparticles in the lab. If there's anything missing or looks damaged, contact us immediately at support@vsparticle.com or using the contact details at the top of this page! A damaged power supply cable may temporarily be replaced by a similar cable, but ensure it has a functional protective earthing terminal.

Detailed system description

A visual reference and detailed description of the components that are part of the VSP-G1 system is provided on the Detailed System Description page. This includes a full reference of the warning labels and symbols found on the machine.

Setting up

Setting up the base unit

Mounting the reactor assembly

When shipped, the reactor assembly is attached to the transport plate in the packaging. The electrodes have already been installed. In the case you want to replace the electrodes, please see the electrode replacement protocol in the System care section of this manual.

To confirm that the reactor assembly is correctly assembled, use a digital multimeter (DMM) to measure the resistance between the reactor chamber and the ground point on the back of the system. Image needed. The resistance should be <0.1 Ohm.

Process connections

Warning: Important notes about carrier gases:

|

Here, we'll discuss a simple set-up using one inlet and outlet using Swagelok connectors. On this page you'll find much more information on the available configurations and connections.

Flow configurations

content needed

| Warning: Do not use a rigid gas connection on the gas inlet valve. You can damage the reactor if the valve is not free to move during the homing sequence. |

Final set up checklist

Content needed (including ensuring that the system is grounded)

Electronics

Grounding the system

The spark generator uses the ground from the mains plug for safety. Use only certified cables and properly wired wall outlets. The separate functional earth terminal on the back of the base unit (#21 in the base unit back diagram above) is internally connected to the mains connector ground, and should be independently connected to the protective ground in the case a recommended mains power supply plug is unavailable.

Power supply connections

After assembling the base unit and reactor, plug in the power supply and the communication cable.

Manual controls

content needed

identification and description of operating controls and their use in all operating modes

Your customised setup

Your particular deposition requirements and research needs will result in a system setup that is different from others. In all cases, however, the following requirements help ensure that the system works efficiently and safely:

- Working system that allows compartmentalisation of the reactor and the deposition system;

- Gas pressure monitoring tool;

- Deposition system; and

- Safe exhaust (fume hood with HEPA+ filters, for example) for the outflowing gas.

A guide to a reference setup is available to help designing basic setup that fulfills these requirements on the VSP-G1 Reference setup page.

Operating the system

| Warning: Do not handle or open the system while particles are being generated and while gas is flowing. |

Basic operating procedures

An abridged form of this section is also available as a Quick Start Guide.

Building a simple setup

The following basic operating procedure is for a simple setup pictured below, which comprises several operating units: a gas source and flow system, a particle source (the VSP-G1 unit), a pressure gauge, a deposition system and exhaust filters. To complete the setup, the units are connected with tubes, piping, fittings, valves and so on. The ball valves (![]() ) in this setup help compartmentalize the overall system for leak testing and for safe disconnection. Each setup will be different, depending on your individual needs, but the concepts described here should generally be valid.

) in this setup help compartmentalize the overall system for leak testing and for safe disconnection. Each setup will be different, depending on your individual needs, but the concepts described here should generally be valid.

To reduce particle losses, please take the following guidelines into account:

- Keep the tubing length between particle source and deposition system as short as possible to reduce diffusive losses.

- Use conductive tubing (metal or conductive polymer) in particle carrying lines to reduce electrostatic losses.

- Do not use flow controllers (e.g. needle valves, mass flow controller) in particle lines, as particles will clog up the controller.

- Usually the controller can be placed in another (particle free) line, or downstream of the deposition system, behind a filter.

- If flow control is absolutely needed in a particle line, use an orifice.

- Avoid constrictions that can function as a particle trap. I particular:

- Use ball valves with a wide bore.

- Avoid fibers and meshes.

[TC: IS THERE A CODE FOR AUTOMATICALLY RESIZING THE IMAGE BASED ON BROWSER SIZE? USEFUL FOR OPERATORS ACCESSING MANUAL USING TABLETS IN THE LAB]

Building a setup takes three steps:

- Design/draw/sketch your flow diagram, including sensors, valves and filters.

- Assemble the VSP-G1 (see Assembling the system

- Assemble the rest of the setup according to your flow diagram.

- Check the system for leak tightness and make adjustments if necessary. (See Checking for leaks.)

Compartmentalisation

For safety reasons, we recommend compartmentalisation of every unit within the setup that regularly opens up to the atmosphere to allow for easy dismantling in a safe manner. In the setup described here, we use two valves on both sides of the deposition chamber which allows us to easily seal off both the reactor and the rest of the setup. When the deposition chamber is removed, it can be safely transported to a safe working location, such as a fumehood or glovebox, in order to take out the sample. Meanwhile, the rest of the setup, which often contains a significant amount of nanomaterial, remains safely sealed.

Pressure safety

The internal pressure should not exceed +1.2 bar or there is an increased risk of failure of the gaskets and/or seals in the reactor, causing leaks and risk of nanoparticle exposure. A build-up of pressure within the system might be an indicator of obstruction, either within the reactor, the deposition system or in the filtration system. Ideally, a pressure sensor at the reactor inlet is used to automatically switch off the gas supply. Stop spark production and gas flow immediately when pressure reaches +1.2 bar to determine the source of obstruction and resolve the issue. See System care for cleaning procedures.

Checking for leaks

Start nanoparticle production

- Ensure that the system is leak tight.

- Power up all systems.

- Ensure that the path to the exhaust is clear.

- Start gas flow.

- Set target voltage and current using the dials on the front of the VSP-G1 base unit.

- Press the start button to begin production.

- To stop production, press the start button again.

==== Stabilising the system ==== We recommend leaving the system to equilibrate/stabilise for 15-30 minutes, depending on your specific needs. This time allows the system to warm up, and the surface of the electrode tips to be refreshed and removing, if any, surface oxides.

Remove your sample

When the deposition system is full or when you’ve produced the desired amount of nanoparticles,

- Stop particle production.

- Flush the system (see Flushing the system).

- Stop the gas flow.

- Take out your sample following the procedure for your deposition system, taking the necessary precautions to prevent/reduce exposure to nanoparticles.

To remove our sample in the setup above, we stopped particle production, flushed the system (9 x τ), closed off the four valves surrounding the deposition system (see image to the right... or link to view image on another page) and disconnected the deposition system from the setup. We then took the deposition system, still closed, to the fume hood where we could proceed to remove our sample safely.

find an appropriate location for this section. It was an information box and I removed all information boxes by incorporating all of the text within the overall document. This is the only one I couldn't find a way to make FIT.

Ways of making the system safe before opening: Flush the system. Depressurise the system. Stop gas flow.

Remote controlled operation

The VSP-G1 can be controlled remotely via its RS232 interface at the back of the system. A full discussion of the command structure, functions and limitations can be found in the Remote control guide.

Miscellaneous operating protocols

Leak tightness protocol

Testing for leak tightness is an essential part of preparing the system for particle production to optimise safety and minimise unnecessary exposure to nanoparticles.

- After checking the flow connections, ensure that the pressure gauge is turned on (and functioning), close the system (see diagram of a sample setup below), slowly turn on the gas flow until the system is full (before it reaches +0.4 bar), and turn it off. The internal pressure should remain the same if the system is leak tight and you can proceed to "Start nanoparticle production".

- If the pressure decreases, there is a leak within the system. Release the pressure within the system before isolating the leak to resolve it.

'Step 3: Partial compartmentalisation of the particle source to check for leak tightness. - Start with the first enclosed system after the input gas flow. In the next diagram based on our basic setup, the first system we check is the VSP-G1 unit (our particle source). Compartmentalise this section from the rest of the setup by closing the valve following the particle source. (In our case, we turned off the valve immediately after the pressure gauge so that we wouldn’t need to disconnect anything.) Check the pressure by turning on the gas flow slowly and turning it off. If pressure remains constant after the gas flow has been stopped, this section is leak tight and you can move on to step 5.

- If pressure decreases, however, check that all connections are sufficiently tightened (if you open any connections, make sure that you’ve turned off gas flow and/or lowered pressure to a safe level). Tighten the connections and/or replace the tubing wherever necessary. Repeat the procedure until the pressure remains constant after the gas flow is turned off.

- Repeat these steps for every enclosed section (see diagram below) of the setup until the system is leak tight.

- After completing the leak tightness protocol and resolving any leaks, test the leak tightness of the whole system by opening all valves and then closing the last valve (using the same set up as shown in Step 1).

- Once the entire system is leak tight, it is ready for nanoparticle production.

If leaks persist:

- Check the proper installation of the blind caps and the pressure gauge connections;

- Try using soap solution: carefully apply a soapy solution to the external surface of every possible joint (especially the valve connectors). Where there’s a leak, bubbles should form. If this does not reveal the leak, do the same test on the external surfaces of the tubing for possible leaks; and/or

- Check your filtration system: the procedure for checking leak tightness of the filtration system varies depending on how it is set up.

Controlled-air protocol

| Warning: Small metal nanoparticles can be extremely reactive. Spark-generated particles made in clean gases can be pyrophoric, presenting a risk of fire when suddenly exposed to air. |

content neededgradually introduces small amounts of air to stabilize the system before opening

Flushing the system

Notification: Flushing the system greatly reduces the risk of nanoparticle exposure when opening the unit for any reason.

To reduce risk of operator exposure, the system should be flushed before opening. The easiest way to flush is by flowing gas with the spark switched off. The time required to flush the system depends on residence time Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \tau} ,

the volume Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle {V}} of the system (operating volume of the VSP-G1 is approximetly 0.3 l), and the flow rate . As a general guideline, one should flush the system for at least 9 times the residence time. With a flow rate of 1 l/min, this takes about 3 minutes.

System care

When to clean the reactor and replace the filter(s)

Clean the reactor whenever you replace the electrodes, the reactor is dirty, or after 100-1000 hours of operation (which in turn depends on your operating conditions: if making more particles, clean more often). If higher settings are needed to maintain a spark flow, it is possible that the reactor needs to be cleaned to prevent spark obstruction which can possibly lead to spark misfiring within the reactor system. If the pressure within the system increases even with the valves open, it is possible that the filter is full and needs to be replaced.

Maintenance protocols

TVP and Vincent: consider adding how-to videos

There are several maintenance protocols for the VSP-G1. Although the system requires no regular maintenance by the end user, cleaning the reactor periodically is recommended, especially after a change of electrode material. To prevent exposure to nanoparticles and to ensure safe and efficient cleaning, follow the protocols set out in the Maintenance protocols section. The procedure to replace electrodes is also discussed there.

Safe handling and storage

content needed

Disassembly

content needed

General disposal guidelines

content needed

Safe transportation

content needed

Troubleshooting

There are several possible issues that may arise during normal operation of the VSP-G1. A more thorough description of all error codes and ways to resolve these are listed in the Troubleshooting guide.

Glow mode

Occasionally the spark voltage drops suddenly, and a weak arc may be seen between the two electrodes. This is caused by a too high charging current. If this occurs directly after changing the spark voltage or spark current set point, the control system in the VSP-G1 will likely correct the situation. If not, the chosen set point cannot be maintained in spark mode. Increase the spark voltage or decrease the operating current to correct the situation.

Interlock errors

| Message on display | Cause | Resolution |

|---|---|---|

| Interlock err. 7 | Motor controller failure | The motor controller reports a failure. This can be due to:

|

| Interlock Error 8 | Broken interlock switch | One of the interlock switches is broken or has a broken connection. Verify both reactor mounting pins are properly secured and that the reactor is properly mounted on the base unit. Press both dials to clear the error and try again. If the error persists, contact VSParticle. |

| Interlock Error 9 | Open interlock switch | One or more interlock switches are in the open state. Verify both reactor mounting pins are properly secured and that the reactor is properly mounted on the base unit. Press both dials to clear the error and try again. |

Electrode alignment

When the VSP-G1 starts aligning electrodes during start-up, several sounds may be heard:

- Quick hammering. This occurs occasionally when the electrode is in an unusual position (e.g. after maintenance/cleaning of the reactor has been performed) and cannot move in the expected direction. This is normal. The sounds should not last more than a second and the system corrects itself and completes the alignment procedure. If the sounds persist for more than a few seconds, switch off the VSP-G1 using the main power switch at the back. Follow the instructions for a blocked motor found under the Interlock err. 7 entry of the interlock errors section above.

- Clicks. These occur at the boundaries of the adjustment range and are no cause for concern.

- Vibrations or rattling. This can occur when there is tension on the gas inlet of the left end cap, restricting free movement or due to wear of the transmission. Check that the gas inlet is free to move. If these sounds occur regularly, contact VSParticle.

When the electrode alignment sequence fails, this is displayed as Interlock err. 7. Refer to the interlock error section above for possible resolutions.

Further troubleshooting

Refer to the Troubleshooting guide for further troubleshooting your VSP-G1.

When to contact VSParticle

- If the system keeps reverting to interlock without apparent reason.

- If sparks can be heard or seen in any location other than between the electrode tips.

Accessories and replacement parts

Use only VSParticle approved parts. All parts related to the reactor assembly must be examined and/or supplied by VSParticle. Contact us for more information.

Specifications of replaceable parts that can be obtained by other suppliers:

Fuses - The fuse holder accepts 5x20mm T2.5A/250V fuses.

Power cable - IEC-content needed.

RS-232 cable - any standard RS-232 cable is suitable.

Appendices

VSP-G1 technical specifications

Additional information about the VSP-G1 operating window, electrical specifications and output can be found on the Technical Specifications page.

Environmental Conditions

The VSP-G1 is designed to be safe under the following normal environmental conditions:

- Indoor use;

- Altitude up to 2,000 m;

- Temperature 5 °C to 40 °C;

- Maximum relative humidity 80 % for temperatures up to 31 °C decreasing linearly to 50 % relative humidity at 40 °C;

- Mains supply voltage fluctuations up to ±10 % of the nominal voltage;

- Transient overvoltages up to the levels of overvoltage category II;

- Temporary overvoltages occurring on the mains supply; and

- Pollution degree 2.

Protocol index

This section has been commented out. Use edit to view old content.

Residual risks

This section has been commented out. Use edit to view the original table.

EC Declaration of Conformity

top

version for user documentation does not need to show signature nor serial number

Warranty

Warnings

Note: I left all of the warning labels from the original draft of the user manual. Not all have been inserted into the document itself. These can be edited for an "Important Safety Guidelines" document to be shipped with the new VSP-G1 unit. - Kate

All warnings hidden for now, please use edit to view the commented section.