VSP-G1 Detailed System Description: Difference between revisions

T.coppejans (talk | contribs) |

T.coppejans (talk | contribs) m (→Symbols) |

||

| (18 intermediate revisions by 2 users not shown) | |||

| Line 17: | Line 17: | ||

| 5 || Viewport | | 5 || Viewport | ||

|- | |- | ||

| 6 || Viewport | | 6 || Viewport cover | ||

|- | |- | ||

| 7 || O-ring and clamp for the viewport (opened/closed with a tool) | | 7 || O-ring and clamp for the viewport (opened/closed with a tool) | ||

|- | |- | ||

| 8 || Gas inlet | | 8 || Gas inlet | ||

|- | |- | ||

| 9 (x3) || Gas | | 9 (x3) || Gas connection (inlet or outlet) | ||

|- | |- | ||

|10 (x2) || Alignment pins | |10 (x2) || Alignment pins | ||

| Line 40: | Line 40: | ||

{{Warning||Do not open the topcaps nor use the power supply accessible via the topcaps as an outlet.}} | {{Warning||Do not open the topcaps nor use the power supply accessible via the topcaps as an outlet.}} | ||

The viewport (#5) allows you to do a visual check of the electrode tips (Cu electrodes come with the standard VSP-G1 unit, already mounted in the reactor housing) without opening the reactor housing. It will be necessary to remove the viewport for cleaning and maintenance activities, but under normal conditions the viewport must be kept in place to reduce the risk of exposure to high voltage and nanoparticles. For this reason, the viewport is attached to the reactor using an O-ring and clamp (#7), which can only be removed by the use of a tool. The viewport | The viewport (#5) allows you to do a visual check of the electrode tips (Cu electrodes come with the standard VSP-G1 unit, already mounted in the reactor housing) without opening the reactor housing. It will be necessary to remove the viewport for cleaning and maintenance activities, but under normal conditions the viewport must be kept in place to reduce the risk of exposure to high voltage and nanoparticles. For this reason, the viewport is attached to the reactor using an O-ring and clamp (#7), which can only be removed by the use of a tool. The viewport cover (#6) can be removed from the viewport for a better view of the electrodes, but it is necessary to keep the coverin place during operation due to UV radiation given off by the spark. | ||

{{Warning||Do not remove the | {{Warning||Do not remove the cover on the viewport, which provides eye protection. If the viewport needs to be cleaned, make sure the spark generator is turned off and the reactor has been relocated to a safe environment.}} | ||

The unit is packed with four blind caps (not pictured) to be installed on any of the four | The unit is packed with four blind caps (not pictured) to be installed on any of the four gas connections (#8 and #9 in the above diagram) that will not be used in your setup. It is important that the left connection, labeled "INLET ONLY" (#8), is only used for a gas inlet connection. It is also important that the connection is flexible, allowing the tube freedom of lateral movement during the electrode alignment procedure. | ||

=== Transport plate === | === Transport plate === | ||

| Line 50: | Line 50: | ||

[[image:Mount tool.PNG|thumb|none|The transport plate.]] | [[image:Mount tool.PNG|thumb|none|The transport plate.]] | ||

The transport plate is similar to the mount plate that connects the reactor to the base unit, but it contains | The transport plate is similar to the mount plate that connects the reactor to the base unit, but it contains ledges that help ensure that parts of the reactor are aligned properly when opening/closing the clamps (#3). It provides a stable surface for working with the dismounted reactor and/or transporting it to a safe environment for maintenance activities. | ||

For your safety and to minimize risk of dropping/damaging the reactor, ensure that you always: | For your safety and to minimize risk of dropping/damaging the reactor, ensure that you always: | ||

* attach the reactor to the transport plate using the alignment pins (#10); | * attach the reactor to the transport plate using the alignment pins (#10); | ||

| Line 57: | Line 58: | ||

=== Base unit === | === Base unit === | ||

<mark>Image of the front view of the base unit was changed on 31 January to show #17 on both sides of the unit (handholds). Make sure that this image is visible on this page.</mark> | <!--<mark>Image of the front view of the base unit was changed on 31 January to show #17 on both sides of the unit (handholds). Make sure that this image is visible on this page.</mark>--> | ||

[[image:Base unit front paint by number.png|full|none|Front view of the base unit with the reactor mount plate.]] | [[image:Base unit front paint by number.png|full|none|Front view of the base unit with the reactor mount plate.]] | ||

| Line 96: | Line 97: | ||

|} | |} | ||

The base unit contains the motor for operating the spark generator. The base unit also contains the manual controls for fine tuning the operation of the spark generator, from spark frequency (#15) to the amount of power to the spark production (#14). On top of the base unit is the mount plate for connecting the reactor housing to the base unit. The alignment plates (#12) help ensure the reactor is aligned properly when mounted. Using the handholds on the sides of the base unit (#17), please place it on a stable flat surface that provides free physical access to the gas input and output | The base unit contains the motor for operating the spark generator. The base unit also contains the manual controls for fine tuning the operation of the spark generator, from spark frequency (#15) to the amount of power to the spark production (#14). On top of the base unit is the mount plate for connecting the reactor housing to the base unit. The alignment plates (#12) help ensure the reactor is aligned properly when mounted. Using the handholds on the sides of the base unit (#17), please place it on a stable flat surface that provides free physical access to the gas input and output connections (#8 and #9), and provides freedom of access to the power controls and plug (#13, #18, and #20). | ||

The on/off power switch (#18) as well as the connection plugs for power (#20), communication (#22) and fuse (#19) are located on the back of the base unit. Also located on the back of the base unit is a functional earth terminal (#21). The fuseholder accepts | The on/off power switch (#18) as well as the connection plugs for power (#20), communication (#22) and fuse (#19) are located on the back of the base unit. Also located on the back of the base unit is a functional earth terminal (#21). The fuseholder accepts 5x20mm T2.5A/250V fuses. | ||

=== Other === | === Other === | ||

[[File:IEC_power_cable.jpg|thumb|150px|right|Power supply cable]] | |||

Power Cable with ground - this cable provides the power supply to the system while grounding the system against electrical surges that might cause electrical shock. If the power cable provided with the VSP-G1 unit is not functional, '''''please use a power cable with an integrated protective earthing terminal'''''. Otherwise, take measures to ensure that the system is earthed (such as using the functional earth terminal, #21). See also the [[VSP-G1_User_Manual#Electronic_connections | the Electronic connections section of the user manual]]. | |||

== Symbols == | |||

= | |||

Below is a full list of the labels affixed to the VSP-G1 unit with a short description and links to relevant locations within this manual for more detailed information. | Below is a full list of the labels affixed to the VSP-G1 unit with a short description and links to relevant locations within this manual for more detailed information. | ||

{| class="table table-bordered table-striped" | {| class="table table-bordered table-striped" | ||

| Line 117: | Line 115: | ||

| Lower right hand corner of the top of the base unit. | | Lower right hand corner of the top of the base unit. | ||

| All purpose warning label for the operator to read and fully understand the User Manual (and all warnings) before use. | | All purpose warning label for the operator to read and fully understand the User Manual (and all warnings) before use. | ||

| Refers to the entire User Manual. Information about leak tightness can be found in the | | Refers to the entire User Manual. Information about leak tightness can be found in the [[VSP-G1_Operating_and_maintenance_guide| operating and maintenance guide]]. | ||

|- | |- | ||

| [[File:Reactor housing danger.png|thumb|200px|center|Do not operate without reactor]] || On the mount plate underneath the reactor housing. || Do not remove reactor housing when running the spark generator. || See | | [[File:Reactor housing danger.png|thumb|200px|center|Do not operate without reactor]] || On the mount plate underneath the reactor housing. || Do not remove reactor housing when running the spark generator. || See [[VSP-G1_User_Manual#Mounting_the_reactor_assembly | mounting the reactor assembly section in the user manual]] for more information. | ||

|- | |- | ||

| [[File:High voltage tamper resist updated.jpeg|thumb|128px|center|High voltage warning]] || On one of the screws of the cover plate at the top of each reactor end cap. | | [[File:High voltage tamper resist updated.jpeg|thumb|128px|center|High voltage warning]] || On one of the screws of the cover plate at the top of each reactor end cap. | ||

| Line 125: | Line 123: | ||

| There are no user-serviceable parts inside. For service personnel only. | | There are no user-serviceable parts inside. For service personnel only. | ||

|- | |- | ||

|[[File:Warranty void.jpeg|thumb|128px|center| Warranty seal ]] || On one of the screws holding a plate of the base unit housing ||Warranty void if seal is broken. There are no user-serviceable parts in the reactor base unit. Do not remove any of the plates, additional warranty seals are present inside the housing on all cover plates. || Refer to the [[# | |[[File:Warranty void.jpeg|thumb|128px|center| Warranty seal ]] || On one of the screws holding a plate of the base unit housing ||Warranty void if seal is broken. There are no user-serviceable parts in the reactor base unit. Do not remove any of the plates, additional warranty seals are present inside the housing on all cover plates. || Refer to the [[VSP-G1_User_Manual#Troubleshooting|Troubleshooting section in the user manual]] when you encounter issues with the base unit or contact VSParticle. | ||

|- | |||

| [[File:Viewport clamp.png|thumb|200px|center|View port clamp]] || On the viewport clamp. || Use this viewport clamp only for attaching the viewport to the reactor assembly. || See [[VSP-G1_Detailed_System_Description#Reactor_assembly|the section on the reactor assembly above]]. | |||

|- | |||

| [[File:UV light warning.png|thumb|200px|center|UV warning]] || On the outer rim of the view port cover. ||UV radiation is harmful to the eyes, do not remove the viewport cover when the spark generator is in use. || See [[VSP-G1_User_Manual#Mounting_the_reactor_assembly | mounting the reactor assembly section in the user manual]] for more information. | |||

|- | |||

| [[File:UV light danger.png|thumb|200px|center|UV exposure]] || On the outer rim of the view port. || UV radiation is harmful to the eyes, put the viewport cover on the viewport before running the spark generator. || See [[VSP-G1_User_Manual#Mounting_the_reactor_assembly | mounting the reactor assembly section in the user manual]] for more information. | |||

|- | |||

| [[File:Gas inlet only.png|thumb|128px|center|Use as gas inlet only ]] || On the gas inlet of the left reactor end cap. ||Gas inlet connection only. || See [[VSP-G1_Detailed_System_Description#Reactor_assembly|the section on the reactor assembly above]]. | |||

|- | |||

| [[File:Machine label.png|thumb|200px|center|VSP-G1 type plate]] || On the back panel of the VSP-G1 base unit. || Important technical specification information relevant to running the VSP-G1 unit, contact information, and warning against opening the system (no user replaceable parts). || For information about electrical supply, see [[VSP-G1_User_Manual#Electronic_connections | the electronic connections section of the user manual]], for information about pressure safety, see [[VSP-G1_User_Manual#Gas_pressure_monitoring | the gas pressure monitoring section of the user manual]] for more information. | |||

|- | |||

| [[File:Functional earth.png|thumb|128px|center|Functional earth terminal]] || On back of the base unit, above the functional earth terminal. || Functional earth terminal for extra grounding protection. || See [[VSP-G1_User_Manual#Electronic_connections | the electronic connections section of the user manual]] for more information. | |||

|- | |||

| [[File:RS232.png|thumb|128px|center|RS232 port ]] || On back panel of the VSP-G1 base unit, above the RS-232 communication port. || RS-232 communication port. || See [[VSP-G1_User_Manual#Electronic_connections | the electronic connections section of the user manual]] for more information on the connection and the [[VSP-G1_Remote_control_guide | remote control guide]] for setting up remote control. | |||

|} | |||

== Controls and indicators == | |||

{| class="table table-bordered table-striped" | |||

|- | |- | ||

! Control !! Location !! Description | |||

|- | |- | ||

| [[File: | | [[File:Voltage dial.JPG|thumb|200px|center|Voltage dial]] | ||

| Front panel, below bottom left corner of the display. | |||

| The voltage dial is used to set the target voltage value, and to change menu selections. | |||

To set the target voltage value, press the voltage dial. When the voltage reading starts blinking, you can adjust the target value by turning the dial. To fix the selected value, press again, or leave the dial untouched for 2 seconds. | |||

To change a menu selection, first access the menu by pressing and depressing both the Voltage and the current dial simultaneously. Turn the dial to change the menu item. Press the dial to escape the menu without making a selection. | |||

|- | |- | ||

| [[File: | | [[File:Current dial.JPG|thumb|200px|center|Current dial]] | ||

| Front panel, below bottom right corner of the display. | |||

| The current dial is used to set the target current value, and to change menu selections. | |||

Setting the target current value is analogous to the voltage dial. | |||

In the setup menu, turn the current dial to change the value of the menu option. Press it to confirm the selected value. | |||

|- | |- | ||

| [[File: | | [[File:Sparkbutton.JPG|thumb|200px|center|Start button]] | ||

| Front panel, on the left. | |||

| The start button is used to stop or start nanoparticle production. | |||

|} | |||

{| class="table table-bordered table-striped" | |||

|- | |- | ||

! Indicator !! Location !! Description | |||

|- | |- | ||

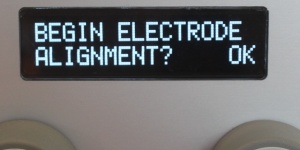

| [[File: | | [[File:Display.JPG|thumb|300px|center|Display]] | ||

| Front panel, mid center. | |||

| The display is used to show the status of the machine. The bottom row is used to display the function currently associated to pushing the control dials. In the image shown here, pressing the left dial has no effect, while pressing the right dial starts the electrode alignment sequence. | |||

|- | |- | ||

| [[File: | | [[File:Sparkbutton on.JPG|thumb|200px|center|Start button]] | ||

| Front panel, on the left. | |||

| The start button comprises a red LED ring. The LED is solid red when the system is ready to spark (idle). During startup, electrode adjustments and while sparking, the LED blinks. When in fault or in interlock mode, the LED blinks. | |||

|} | |} | ||

Latest revision as of 15:18, 5 July 2017

System components

Reactor assembly

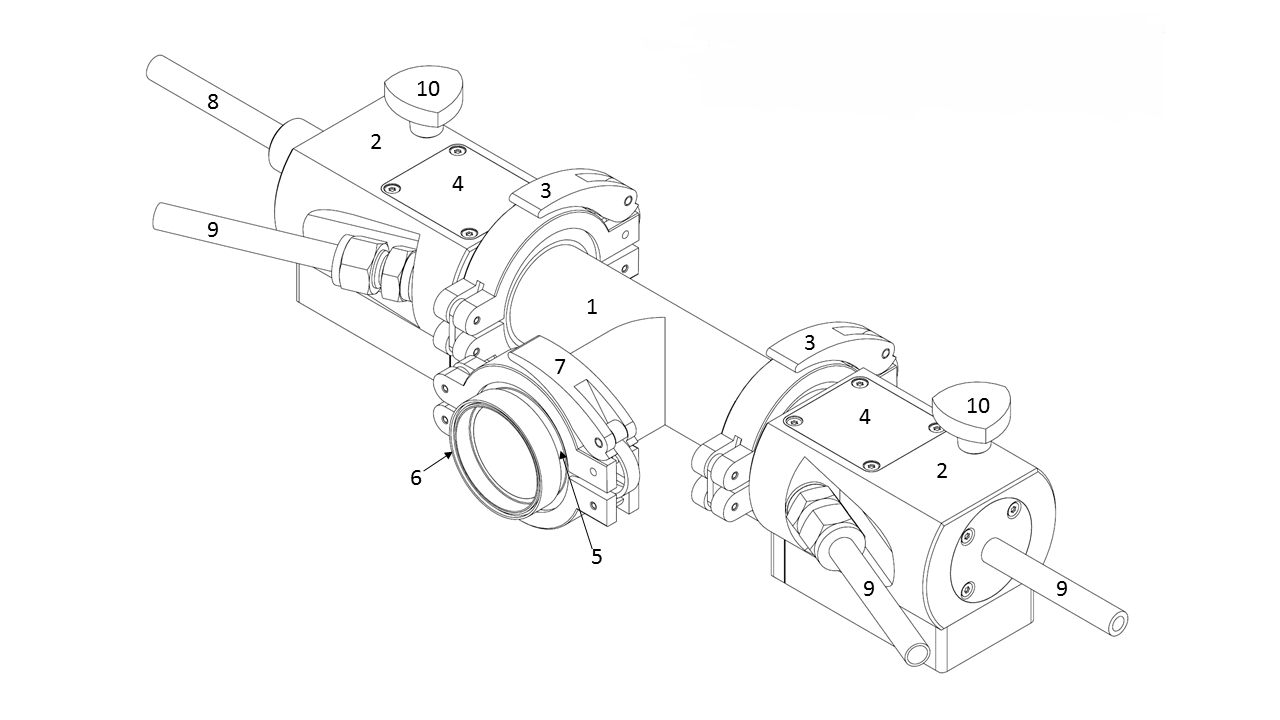

| Part no. in drawing | Description |

|---|---|

| 1 | Reactor housing |

| 2 (x2) | Endcaps |

| 3 (x2) | O-rings and clamps |

| 4 (x2) | Topcaps |

| 5 | Viewport |

| 6 | Viewport cover |

| 7 | O-ring and clamp for the viewport (opened/closed with a tool) |

| 8 | Gas inlet |

| 9 (x3) | Gas connection (inlet or outlet) |

| 10 (x2) | Alignment pins |

| Blind caps (4x), not pictured |

The reactor of the VSP-G1 is where all the action happens during spark generation. It is also the area of highest risk to high voltage, nanoparticle and gas exposure, and UV exposure.

Notification: It is very important that all safety guidelines for the reactor are followed carefully.

The reactor assembly is easily removed from the mount plate (#11 in the base unit diagram below) for cleaning and other maintenance activities to be conducted in safe conditions (such as under a fume hood). The removal of the O-rings and clamps (#3) on either side of the central reactor housing (#1) allow access to electrodes for replacement and cleaning.

The endcaps (#2) contain the power supply to the motor powering the reactor. The power supply is accessible by the topcaps (#4), for VSParticle service personnel only.

The viewport (#5) allows you to do a visual check of the electrode tips (Cu electrodes come with the standard VSP-G1 unit, already mounted in the reactor housing) without opening the reactor housing. It will be necessary to remove the viewport for cleaning and maintenance activities, but under normal conditions the viewport must be kept in place to reduce the risk of exposure to high voltage and nanoparticles. For this reason, the viewport is attached to the reactor using an O-ring and clamp (#7), which can only be removed by the use of a tool. The viewport cover (#6) can be removed from the viewport for a better view of the electrodes, but it is necessary to keep the coverin place during operation due to UV radiation given off by the spark.

The unit is packed with four blind caps (not pictured) to be installed on any of the four gas connections (#8 and #9 in the above diagram) that will not be used in your setup. It is important that the left connection, labeled "INLET ONLY" (#8), is only used for a gas inlet connection. It is also important that the connection is flexible, allowing the tube freedom of lateral movement during the electrode alignment procedure.

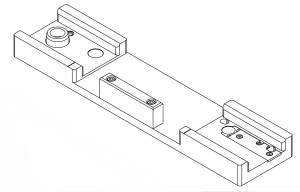

Transport plate

| Warning: Always mount the dismounted reactor assembly to the transport plate to reduce possible damage when handling it for maintenance activities. |

The transport plate is similar to the mount plate that connects the reactor to the base unit, but it contains ledges that help ensure that parts of the reactor are aligned properly when opening/closing the clamps (#3). It provides a stable surface for working with the dismounted reactor and/or transporting it to a safe environment for maintenance activities.

For your safety and to minimize risk of dropping/damaging the reactor, ensure that you always:

- attach the reactor to the transport plate using the alignment pins (#10);

- work with the disconnected reactor in a safe environment, such as under a fume hood; and

- wear gloves to protect the internal surfaces of the reactor housing and to prevent open exposure to nanoparticles.

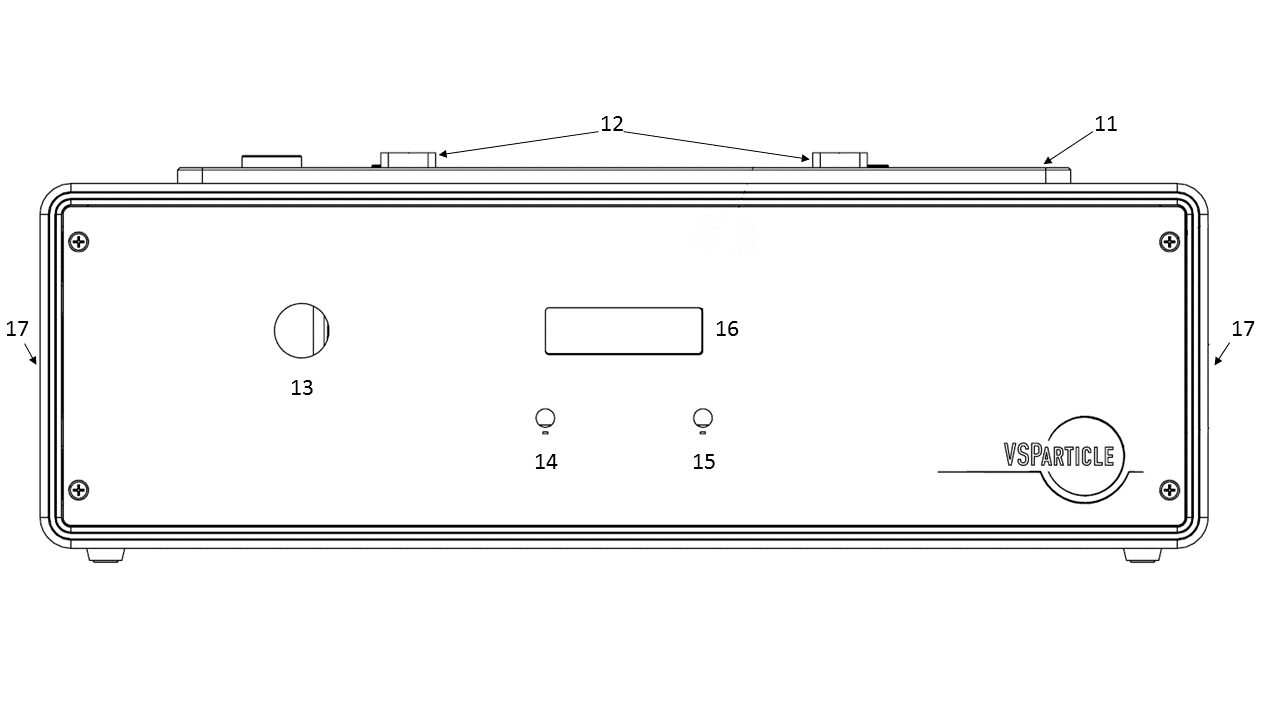

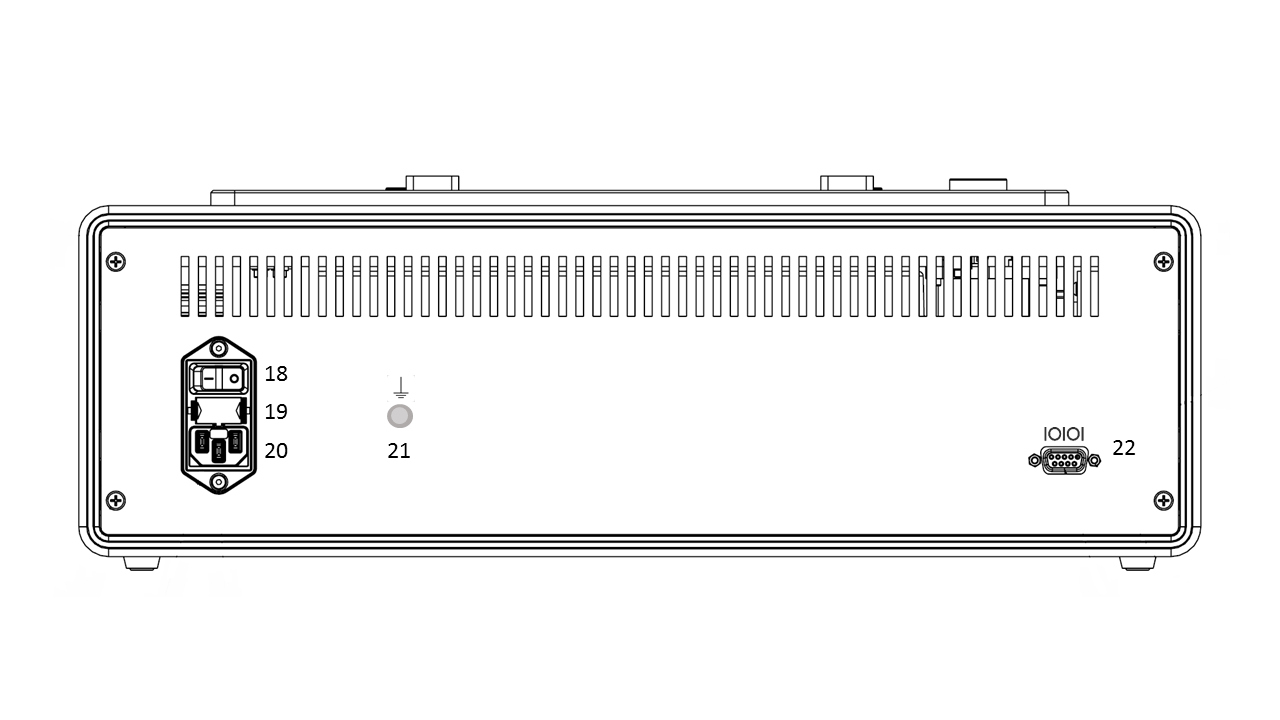

Base unit

| Part no. in drawing | Description |

|---|---|

| 11 | Mount plate |

| 12 (x2) | Alignment plates |

| 13 | Start/Emergency stop button |

| 14 | Spark energy adjustment knob |

| 15 | Spark frequency adjustment knob |

| 16 | Display |

| 17 (x2) | Handholds (on each side of the base unit) |

| Part no. in drawing | Description |

|---|---|

| 18 | On/off switch |

| 19 | Fuseholder |

| 20 | Mains supply plug |

| 21 | Functional earth terminal |

| 22 | RS-232 port |

The base unit contains the motor for operating the spark generator. The base unit also contains the manual controls for fine tuning the operation of the spark generator, from spark frequency (#15) to the amount of power to the spark production (#14). On top of the base unit is the mount plate for connecting the reactor housing to the base unit. The alignment plates (#12) help ensure the reactor is aligned properly when mounted. Using the handholds on the sides of the base unit (#17), please place it on a stable flat surface that provides free physical access to the gas input and output connections (#8 and #9), and provides freedom of access to the power controls and plug (#13, #18, and #20).

The on/off power switch (#18) as well as the connection plugs for power (#20), communication (#22) and fuse (#19) are located on the back of the base unit. Also located on the back of the base unit is a functional earth terminal (#21). The fuseholder accepts 5x20mm T2.5A/250V fuses.

Other

Power Cable with ground - this cable provides the power supply to the system while grounding the system against electrical surges that might cause electrical shock. If the power cable provided with the VSP-G1 unit is not functional, please use a power cable with an integrated protective earthing terminal. Otherwise, take measures to ensure that the system is earthed (such as using the functional earth terminal, #21). See also the the Electronic connections section of the user manual.

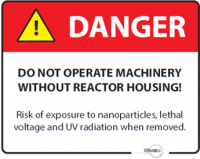

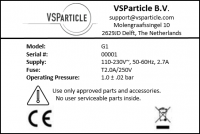

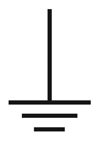

Symbols

Below is a full list of the labels affixed to the VSP-G1 unit with a short description and links to relevant locations within this manual for more detailed information.

| Label | Location | Description | Information location |

|---|---|---|---|

|

Lower right hand corner of the top of the base unit. | All purpose warning label for the operator to read and fully understand the User Manual (and all warnings) before use. | Refers to the entire User Manual. Information about leak tightness can be found in the operating and maintenance guide. |

|

On the mount plate underneath the reactor housing. | Do not remove reactor housing when running the spark generator. | See mounting the reactor assembly section in the user manual for more information. |

|

On one of the screws of the cover plate at the top of each reactor end cap. | Tamper-proof warning stickers protect the high voltage compartments of the reactor end caps. Please contact VSParticle in case of issues with an end cap. | There are no user-serviceable parts inside. For service personnel only. |

|

On one of the screws holding a plate of the base unit housing | Warranty void if seal is broken. There are no user-serviceable parts in the reactor base unit. Do not remove any of the plates, additional warranty seals are present inside the housing on all cover plates. | Refer to the Troubleshooting section in the user manual when you encounter issues with the base unit or contact VSParticle. |

| On the viewport clamp. | Use this viewport clamp only for attaching the viewport to the reactor assembly. | See the section on the reactor assembly above. | |

| On the outer rim of the view port cover. | UV radiation is harmful to the eyes, do not remove the viewport cover when the spark generator is in use. | See mounting the reactor assembly section in the user manual for more information. | |

| On the outer rim of the view port. | UV radiation is harmful to the eyes, put the viewport cover on the viewport before running the spark generator. | See mounting the reactor assembly section in the user manual for more information. | |

|

On the gas inlet of the left reactor end cap. | Gas inlet connection only. | See the section on the reactor assembly above. |

|

On the back panel of the VSP-G1 base unit. | Important technical specification information relevant to running the VSP-G1 unit, contact information, and warning against opening the system (no user replaceable parts). | For information about electrical supply, see the electronic connections section of the user manual, for information about pressure safety, see the gas pressure monitoring section of the user manual for more information. |

|

On back of the base unit, above the functional earth terminal. | Functional earth terminal for extra grounding protection. | See the electronic connections section of the user manual for more information. |

|

On back panel of the VSP-G1 base unit, above the RS-232 communication port. | RS-232 communication port. | See the electronic connections section of the user manual for more information on the connection and the remote control guide for setting up remote control. |