VSP-G1 User Manual: Difference between revisions

No edit summary |

|||

| Line 9: | Line 9: | ||

== Introduction == | == Introduction == | ||

[https://docs.vsparticle.com/w/index.php/G1_User_Manual''top''] | [https://docs.vsparticle.com/w/index.php/G1_User_Manual''top'']<br> | ||

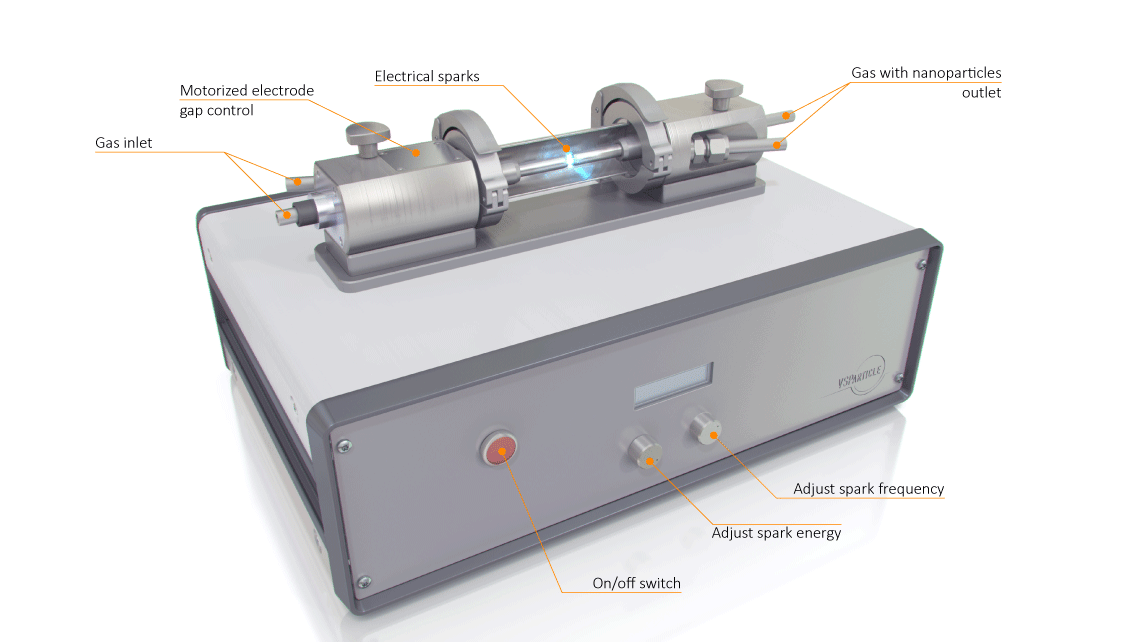

[[Image:Generator_One.png|thumb|left|VSParticle Generator One|''VSParticle Generator One'']] | |||

[[Image:Generator_One.png| | '''''(note about text of introduction... refine this when done with the rest of the manual content and when talking about features, try to link to them appropriately in the manual. For example, when talking about adjusting for particle size, link to the protocol for that)''''' | ||

Congratulations on your purchase of the VSParticle Generator One (VSP-G1). With the VSP-G1, easy production of inorganic nanoparticles from conductive materials is possible with control over size (1 atom to 20 nm) and production rate (xx – xx). | Congratulations on your purchase of the VSParticle Generator One (VSP-G1). With the VSP-G1, easy production of inorganic nanoparticles from conductive materials is possible with control over size (1 atom to 20 nm) and production rate (xx – xx). | ||

Revision as of 14:19, 8 September 2016

This is the comprehensive User Manual for the VSParticle Generator One unit. The Quick Start Guide is available as a quick reference for standard operation of the G1 unit.

VSParticle

Molengraafssingel, 10

2629 Delft

The Netherlands

info@vsparticle.com

www.vsparticle.com

Introduction

(note about text of introduction... refine this when done with the rest of the manual content and when talking about features, try to link to them appropriately in the manual. For example, when talking about adjusting for particle size, link to the protocol for that)

Congratulations on your purchase of the VSParticle Generator One (VSP-G1). With the VSP-G1, easy production of inorganic nanoparticles from conductive materials is possible with control over size (1 atom to 20 nm) and production rate (xx – xx).

Designed for use by researchers studying material properties, the VSP-G1 allows flexibility in the use of different gases and electrode materials for a wider range of combinations. The closed system provides a safer production of nanoparticles and can easily be dismantled for safe transport of produced nanoparticles as well as for system cleaning and maintenance. The VSP-G1 system can be integrated into a larger system for more complex operating procedures.

The production rate depends on the energy input into the spark, and material properties of the electrode. The VSP-G1 operates up to 60W, which corresponds to ablation rates up to ~100 mg/h for e.g. Au. Particle size is a function of the production rate and the flow rate. The spark gap is controlled automatically, allowing continuous operation. The spark generator is designed for a broad operating window, making it suitable for applications ranging from cluster research to materials science.

User service is needed in two situations: Periodic cleaning and replacing of electrodes. In both activities can be performed with a safe, simple and fast (<20 mins) protocol.

The particles are made available as an aerosol, allowing the user to choose a suitable deposition method for his or her substrates. VSParticle can help select/develop a deposition system fitted to your specific needs.

(work in somehow)

Features of the VSP-G1:

- Electrodes can be replaced by user (requires opening and cleaning of reactor).

- Mixing materials at the nanoscale by using electrodes of different materials.

- High purity: Exposes materials: Stainless steel, PTFE, Viton. No polymers near ablation zone. Gas based production eliminates the need for chemicals/surfactants or precursors.

- The output of the system consist out of gas stream filled with particles. There are no polluting by-products formed during production.

- The reactor can easily be customized to allow cross flow, co-flow, through flow (standard) and combined configurations.

How to use this manual

This user manual provides instructions for the set-up, installation, operation and maintenance of a VSP-G1 unit. Before operating the VSP-G1 unit, please read the manual with careful attention to the safety section and to the warnings provided throughout the manual, indicated by the following symbols:

(symbols used in the manual)

| (Short index of manual and a 1 sentence summary of each chapter/section) |

A quick start guide is also included for faster set-up as part of the standard operating procedure. For more information regarding safety and more complex operations as well as troubleshooting and maintenance, please refer to this manual.

Safety

Warning of residual risks

Protective measures

Airborne noise emissions

Foreseeable misuse

Setting up

Intended use

Foreseeable misuse

Workstation

Assembly, installation and connection

Stability conditions

Safe transportation, handling and storage

Operations

Instructions for putting into service and use of the G1 unit

What to do in the case of accident, breakdown or likely blockage

Description of adjustment and maintenance operations and preventive maintenance measures

Instructions to enable safe adjustment and maintenance, including protective measures

Maintenance and Troubleshooting

Error messages and how to resolve them

Possible issues and how to resolve them

Maintenance checklist (before and after normal use)

Maintenance checklist (periodical/occasional throughout product lifetime)

Accessories and Parts Replacement

Tools fitted to G1

Spare parts

Appendices

Detailed communication set up

Detailed specifications not otherwise indicated in manual

Conceptual design and manufacturing drawings and schemes of components, sub-assemblies, circuits, etc.

Descriptions and explanations necessary for the understanding of ˄˄ and operation of electrical equipment

EC Declaration of Conformity

Warranty

Edited by Kate Groves 15:58, 8 September 2016 (CEST)